Plywood boats

Practical Action

Parallel to this development in CAT came an offer to the BBC Muttom from British naval

architect Edwin Gifford and the Intermediate Technology Development Group –ITDG (now

Practical Action) to build and test some prototypes of a new beach landing craft fabricated in

marine plywood using a technique called 'stitch and glue' (see box). Gillet saw that this boat-

building technology could be key to realising their own ideas, and accepted the Gifford-ITDG

proposal.

Having mastered the new technology, the plan for the 'ideal' craft was revived. News of the

new craft spread rapidly along the coast by word-of-mouth, and the cost of Rs7500 (in 1982

prices) seemed well within the reach of the fishermen. Firm orders from kattumaram

fishermen was proof of this.

The instant success of the 'kottarkat' made BBC Muttom and CAT more confident and open to

the requests from other fishermen using different types of traditional crafts. The next request

came from fishermen who wanted a replacement for their dug-out canoes, as large tree trunks

were in very short supply as a result of heavy deforestation. A plywood vallam (see photo)

made using the stitch-and-glue technique was a possible solution. It would have to be stable,

with good rowing and sailing efficiency, and be able to take an outboard motor (OBM).

By the end of 1982, BBC Muttom had designed a new plywood vallam and had outstanding

orders for 26 kottarkats. The rising demand for the new boats was a reflection of both the

technical soundness and the commercial viability of the boat yard. An old experiment was

slowly turning into a successful innovation.

Promoting the innovation

The enthusiasm of the fishermen for the new plywood boats was also the result of several

supply and demand factors not directly related to Muttom.

First, there was the decline in the amount of fish landed by the artisanal fishermen

between 1975 and 1980. The fishermen attributed this to the destructive fishing of

the trawlers.

Secondly, as a result of this perception, there were conflicts at sea, and trawlers were

attacked. But artisanal fishermen felt that it was not enough to curb the trawlers,

they had to fish better too. Mechanical propulsion was the only way to achieve this.

Thirdly, the government's liberal 1980 import policy resulted in the availability of

OBMs in the open market.

Fourthly, the price of traditional craft spiralled because of the acute shortage of light

wood and large trees. Fishermen who were still using the centuries-old craft design

became more open to adopting new models and using new materials.

Commercially feasible

By early 1983, these macro

conditions and the situation along

the south-west coast region

combined to really launch the PWB

commercially. In fact the demand

for the plywood boats brought with

it a host of new, unanticipated sup-

ply problems.

The need for the present boat-

building set-up to work

commercially raised a number of

questions: What institutional

framework would allow expanded

activity in the future? How should

finance questions be resolved?

Should the designs be patented to

ensure that the new technology

remained in the control of those

3

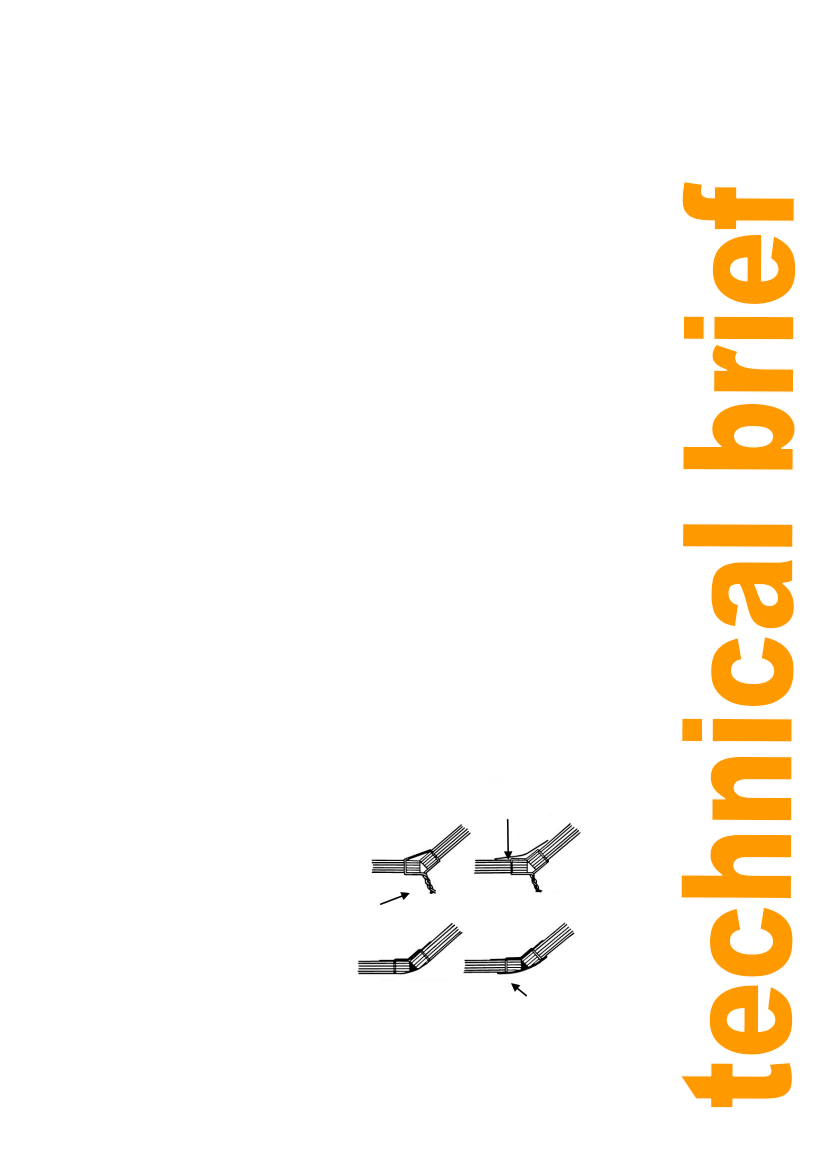

Fibreglass tape on

epoxy glue

Wire ties about

every 20 cm

Tie hammered down

Tie cut-off, edge

rounded, joint filled

with resin and

Fibreglass tape and

epoxy resin

Figsularteed3u:stTohreeppolxyywpouotyd sheets are stitched together using

wire ties and covered with resin and fibreglass tape